Oil Drilling Enhanced Oil Recovery Polyacrylamide

Short Description:

Product Name: Oil Driling Enhanced Oil Recovery (EOR) Polyacrylymide

Molecular Formula: (C3H5NO)n

Molecular Weight: 2--12Million

Ionization Degree: 10--60%

Solid Content: ≥90%

Dissolve Time: ≤60 min

Residual Unit: ≤0.10%

Cas No: 9003-05-8

EINECS No: 231-545-4

HS Code: 3906 9010 00

Package: 25KG Woven Bag or follow buyer's requirement

Certificate: ISO/MSDS/COA

Application: Water treatment

Sample: Available

Craft: Original carrier-free biological enzyme catalysis

Send Email To Us

Product Introduction

Product Information

Polyacrylamide (PAM for short) is a commonly used artificial flocculant. It is easily soluble in water and easily decomposed when the temperature exceeds 120°C. The product has properties such as flocculation, thickening, shearing, drag reduction, and dispersibility. The solid is white or slightly yellow powder, the liquid is colorless and viscous, and the colloidal product is colorless and transparent. Anionic, cationic, nonionic, and zwitterionic polyacrylamide can be obtained by chemical modification.

The homopolymer formed by the polymerization of a single acrylamide is nonionic, and its molecules are not charged. The copolymer formed by the copolymerization of acrylamide and anionic monomers (such as sodium acrylate) is anionic, and its molecules are negatively charged. For the same reason, the copolymer generated by acrylamide and cationic monomers is cationic, and its molecules are positively charged.

The copolymer contains some ionic monomers, which shows partial ionic characteristics. We use the percentage of ionicity to express the charge on the polymer molecular chain. The higher the ionicity, the more charged the molecular chain is. In this way, the ionicity of nonionic polyacrylamide is zero. What charge (i.e. ionicity) and how much charge (i.e. ionicity) the polyacrylamide molecular chain carries are important considerations when selecting polyacrylamide flocculants.

Polyacrylamide is a synthetic polymer with a relatively high molecular weight. The molecular weight of polyacrylamide always refers to the average molecular weight, which indicates the average length of each polymer molecule. The larger the molecular weight, the more chain segments each molecule contains, or the longer the average length of each molecule. From the perspective of molecular weight, the flocculation effect of polyacrylamide is not only related to the molecular weight, but also to the molecular structure (straight chain, branched chain, cross-linked) and molecular weight distribution (wide, narrow).

Product Name | Cationic Polyacrylamide | Molecular Formula | (C3H5NO)n |

CAS NO | 9003-05-8 | Molecular Weight | 2--12 Million |

| EINECS NO | 231-545-4 | HS Code | 3906 9010 00 |

| Ionization Degree | 10--60% | Solid Content | ≥90% |

| Dissolve Time | ≤ 60 min | Residual Unit | ≤0.10% |

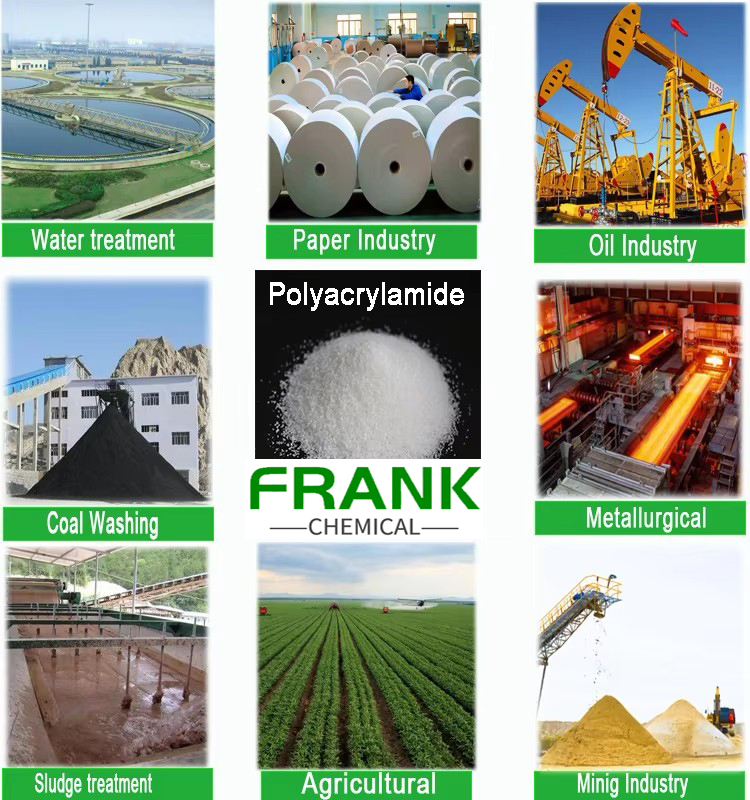

Product Category

It is widely used in oil exploration, profile control, plugging agent, fracturing fluids ,drilling fluids additives.

Also plays an important role in these applications for dropping drilling fluid loss, flocculation, dilution, plugging, shale inhibition, cooling and lubricating the drill bit and drill string, carrying debris, cementing well.

Can meet all the complex requirements of viscosity, temperature, salinity and flooding performance for oil exploitation

The company can customize different types of polymers according to different location conditions (ground temperature, salinity, permeability, oil viscosity) and other indicators of each block of the oilfield, so as to effectively improve oil recovery rate and reduce water content.

Common models are as follows:

Product No. | Electric Density | Molecular Weight | Application |

7226 | Middle | High | Medium low salinity,medium low geotemperature |

| 60415 | Low | High | Medium salinity,medium geotemperature |

| 61305 | Very Low | High | High salinity,high geotemperature |

Details Images

|  |

Application:

Oil Extraction,Enhanced Oil Recovery(EOR) Polyacrylamide:

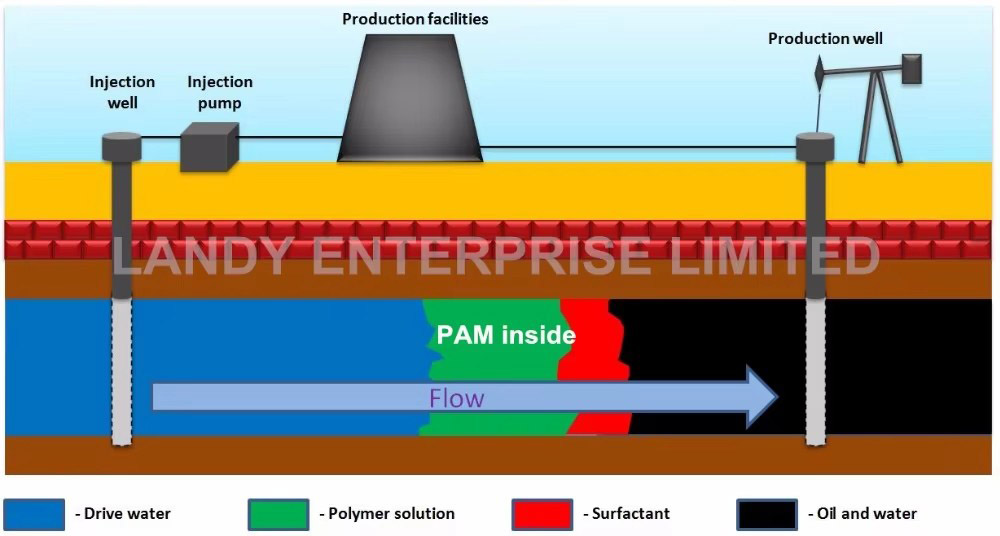

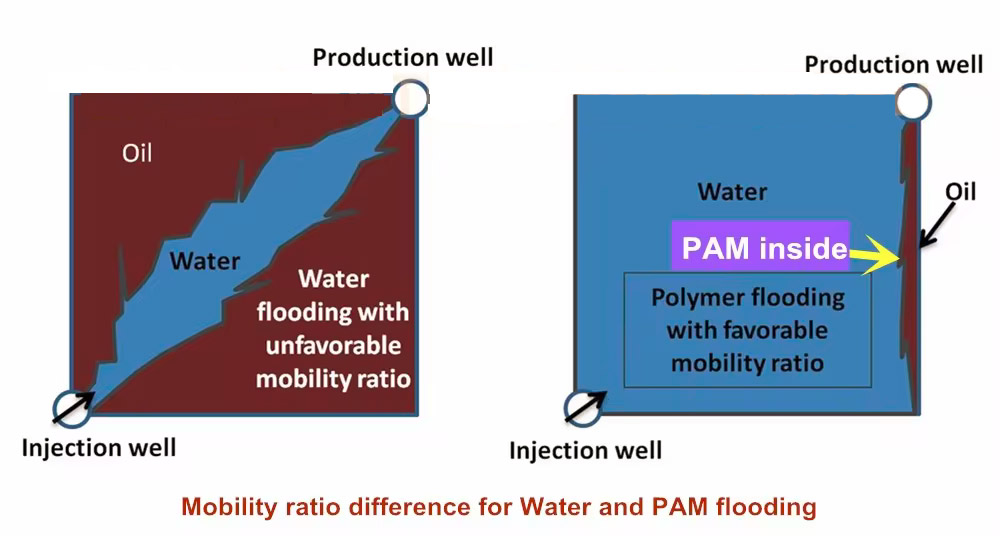

Oil displacement agent refers to the injection of oil from the injection well of the oil field into the underground oil layer in order to improve the recovery rate of crude oil. Oil displacement agent is not injected in primary oil recovery. Secondary oil recovery is characterized by the injection of water and gas (general fluid), and the injected water and gas belong to the oil displacement agent. Tertiary oil recovery is characterized by the injection of special fluids. Different special fluids constitute different oil displacement methods, and different oil displacement methods use different oil displacement agents.

At present, tertiary oil recovery mainly uses polymer oil displacement technology, which is an economical and effective method to improve crude oil recovery. It can improve crude oil recovery by increasing the sweep coefficient of water, and can also improve the microscopic oil displacement efficiency of the core through the viscoelasticity of the polymer solution. When the geological conditions of the reservoir are certain, the effect of polymer oil displacement mainly depends on the performance of the water-soluble polymer used for oil displacement, which is mainly partially hydrolyzed polyacrylamide (HPAM) and its modified polymers. Through copolymerization, chain links with rings are introduced into the structure to improve the temperature resistance.

Direction for use:

1. Usually the product is prepared into solution of 0.1%-0.3% (W/W) for use.

2. Targeted at different purposes, choose the best quantity of reagent via test.

Personal Protection Equipment:

Respiratory: If dusting, wear an effective facemask with a particle filter.

Eye: Use of goggles.

Hand: Plastic gloves.

Skin/Body: Light weight protective clothing.

Handling, Storage and Shelf life:

Handling : Minimize dusting of product.

Storage : Store the powder in cool, dry conditions avoiding humid and wet areas.

Shelf life: 2 years on recommended storage condition.

Package:25kg three in one composite bag, lined with polyethylene

Single package size: 85X50X16 cm Single gross weight: 25.000 kg

Loading Quantity: 20-21Tons /20' FCL no pallet, or 15-18 Tons /20' FCL with pallet.

Package & Warehouse

|  |  |

Package | 25KG Bag |

Quantity | 20-21Tons /20' FCL no pallet, or 15-18 Tons /20' FCL with pallet. |

Polyacrylamide dispersant for papermaking

Polyacrylamide dispersant for papermaking Anionic Polyacrylamide (APAM)

Anionic Polyacrylamide (APAM) Nonionic Polyacrylamide Powder (NPAM)

Nonionic Polyacrylamide Powder (NPAM)